Jafari Refrigeration Industries in Qom

Jaafari Refrigeration Industries, in the field of refrigeration installation, freezing tunnel, chiller, ice bank and compressor repair in Qom

Industrial refrigerator refers to refrigerators designed and manufactured to maintain and maintain temperature -sensitive goods and products on a large scale and capacity. The industrial refrigerator is a controlled environment in which precision temperature and humidity are controlled to ensure the desired conditions and the life of the perishable items. Unlike conventional refrigerators that may have smaller volumes or meet the needs of specific industries, industrial cold stores are usually made of considerable amounts (more than 2 tons) for storage and storage.

The importance of industrial cold storage in various industries

Food Industry

The food industry relies heavily on industrial cold stores to maintain the novelty, safety and quality of perishable food products. Industrial refrigerators allow storing and storing a wide range of food items including fruits, vegetables, dairy products, meat and seafood at specific temperatures and levels. These facilities help prevent corruption, reduce food waste and increase product shelf life by maintaining a cold maintenance chain.

Pharmaceutical industry

in the pharmaceutical industry, maintaining the quality and safety of medicines and vaccines is of great importance. Industrial refrigerators provide controlled environments where pharmaceutical products can be stored at precise temperatures and ensure their efficiency and stability. Many medications, such as specific vaccines and drugs, require a specific temperature range for maintenance and any deviation can make them ineffective or even harmful. They provide temperature sensitive and maintain their healing properties. They also play an important role in the distribution of the drug and allow safe transport and storage across the supply chain.

Chemical Industries

The chemical industries often deal with materials that need to be maintained at controlled temperatures. Industrial refrigerators provide suitable conditions for the storage of various chemicals such as specialized chemicals, raw materials and intermediaries. The industrial refrigerator, by maintaining temperature conditions, prevents chemical reactions, destruction and loss of the nature of materials. This environment by stabilizing and stabilizing chemicals by stabilizing and storing the chemicals and contributing to the overall efficiency of chemical production processes. Slow. In addition, industrial refrigerators also provide safety benefits by reducing the risk of fire, explosion or hazardous reactions associated with inappropriate maintenance of some chemicals.

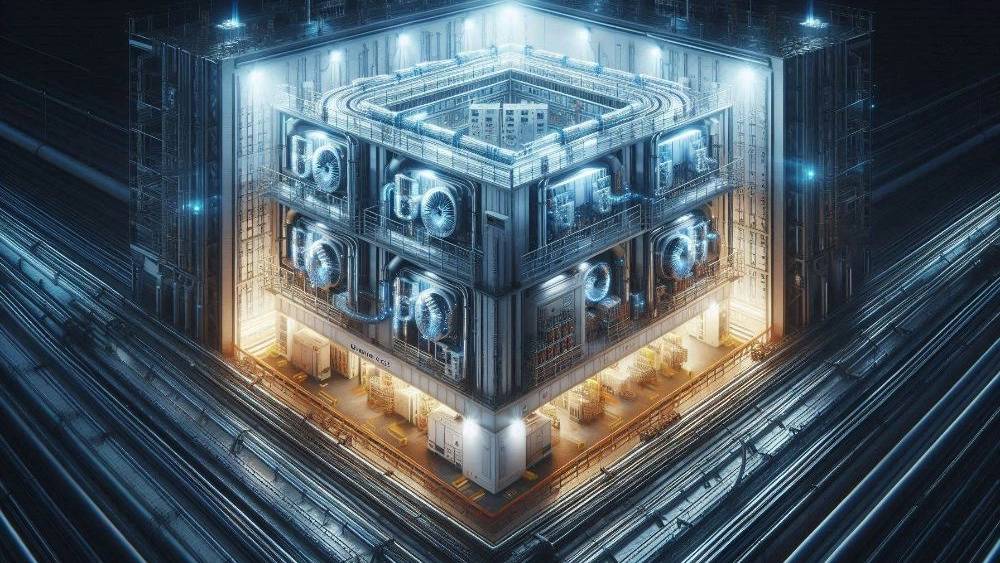

Double circuit industrial cold storage

The two -circuit refrigerator becomes a kind of refrigeration system that includes two refrigeration circuits, while the two circuits are completely independent or separate. Each circuit contains its own set of compressors, condensors, evaporators and controllers. The purpose of a two -circuit refrigerator is to improve operational efficiency and flexibility in maintaining a variety of products. These two circuits can work simultaneously or intermittently depending on the need for refrigeration and system needs.

If maintenance or repair in one circuit, another can continue as a reservation or Standby. Give (provided the circuits are independent). In addition, the design of an industrial refrigerator in two circuits enables better control of the temperature range in the refrigerator. Each circuit can be dedicated to specific temperature domains or refrigerated halls that allow careful management of temperature and energy consumption optimization. This flexibility is especially useful in large refrigerators with different temperature conditions for different products.

Industrial cold storage above zero

Zero refrigerator is generally used to store fresh fruits, dried fruits, vegetables, oils and oils and nuts at a temperature of between 1 and 2 degrees Celsius. These refrigerators are usually constructed in areas where shorts to fruit gardens or a special product that requires maintenance in a cold store above zero. In some cases, gardeners or product owners are constructed as a co -operative company.

Industrial cold storage below zero

Industrial refrigerator below zero is a commodity maintenance facility designed and built to maintain temperatures below zero, usually -5 degrees Celsius. This type of refrigerator is very essential and efficient for jobs that require and maintain products that require Deep Freeze (Deep Freeze). It guarantees the quality, safety and long -lasting of items such as meat, poultry, fish, ice cream, and so on. Underline refrigerators are equipped with refrigeration systems proportional to operating temperature. Better and thicker insulators should also be used for an industrial refrigerator below zero. The facility should be carefully designed to prevent temperature fluctuations, minimize moisture and maintain product quality.

Technical specifications of industrial cold storage

Temperature Control and Sustainability of Conditions

One of the primary technical features of industrial refrigerators is precise temperature control and stability. These installations are equipped with advanced refrigeration systems and temperature control mechanisms to maintain a constant and optimal temperature range for stored products.

Humanity Control

In addition to temperature control Industrial cold stores may also use humidity control systems. Depending on the need for stored products, moisture surfaces can be adjusted to prevent high or low moisture. Moisture Control helps maintain product tissue, prevent microbial growth and minimize the risk of product breakdown.

Insulation Insulation Effective Effective Insulation A Key Technical Feature in It is industrial cold stores. High quality insulation materials and proper installation techniques minimize heat transfer and ensure that the refrigerator continuously maintain its optimal temperature.

Air circulation management and interior air replace Industrial refrigerators

Industrial refrigerators with circulation systems and optimal air circulation use to ensure the uniform distribution of temperature and humidity throughout the refrigerator. In addition to the proper air circulation in the storage of some products such as breathing fruits, the air inside the refrigerator needs to be discharged and replaced by the fans. This prevents more gases such as ethylene emitted by fruits. The number of times the time required for air replacement per day is listed in the storage standards of each product in the refrigerator.

Supervisory and Control Systems

Modern industrial refrigerations equipped with monitoring systems And advanced controls to provide information online about temperature, humidity and other vital parameters. These systems allow remote monitoring, data registration and alerts in the event of a deviation from the specified range. With continuous monitoring and regulating conditions, facility managers can quickly handle any problems, maintain product quality, and ensure compliance with regulatory standards.

Energy Productivity

Energy Productivity is a remarkable point in industrial refrigerators. These facilities are designed to optimize energy consumption through the use of efficient refrigeration systems, insulation and lighting. Different energy saving technologies, such as LED lighting, variable frequency drives for compressors, and heat recovery systems, can be implemented to minimize energy loss and reduce operational costs.